www.acehomeinspections.net

P.O. Box 1993

Alabaster, Alabama 35007

(205)401-3030 |

|

Customer

Sample |

|

Home

Sample

|

|

Real Estate Agent

NONE - OWNER

INSPECTION

|

|

|

Weather:

Clear and Sunny | Inspection

Date

Tuesday, June 14, 2005

Report ID:

01820

| |

Temperature:

80 to 85 degrees |

Inspected By

Jeff Aiken

| |

SUMMARY

www.acehomeinspections.net

P.O. Box 1993

Alabaster, Alabama

35007

(205)401-3030 |

|

Customer

Sample |

|

Home

Sample

|

The following

items or discoveries indicate that these systems or components do not function

as intended or adversely affects the habitabilty of the dwelling; or appear to

warrant further investigation by a specialist, or requires subsequent

observation.

This summary shall not contain recommendations for routine upkeep of a system

or component to keep it in proper functioning condition or recommendations to

upgrade or enhance the function, efficiency, or safety of the home.

This Summary is not the entire report. The complete report may include

additional information of concern to the customer. It is recommended that the

customer read the complete report.

www.acehomeinspections.net

Home inspectors are not required to report on the following: Life expectancy

of any component or system; The causes of the need for a repair; The methods,

materials, and costs of corrections; The suitability of the property for any

specialized use; Compliance or non-compliance with codes, ordinances, statutes,

regulatory requirements or restrictions; The market value of the property or its

marketability; The advisability or inadvisability of purchase of the property;

Any component or system that was not observed; The presence or absence of pests

such as wood damaging organisms, rodents, or insects; or Cosmetic items,

underground items, or items not permanently installed. Home inspectors are not

required to: Offer warranties or guarantees of any kind; Calculate the strength,

adequacy, or efficiency of any system or component; Enter any area or perform

any procedure that may damage the property or its components or be dangerous to

the home inspector or other persons; Operate any system or component that is

shut down or otherwise inoperable; Operate any system or component that does not

respond to normal operating controls; Disturb insulation, move personal items,

panels, furniture, equipment, plant life, soil, snow, ice, or debris that

obstructs access or visibility; Determine the presence or absence of any

suspected adverse environmental condition or hazardous substance, including but

not limited to mold, toxins, carcinogens, noise, contaminants in the building or

in soil, water, and air; Determine the effectiveness of any system installed to

control or remove suspected hazardous substances; Predict future condition,

including but not limited to failure of components; Since this report is

provided for the specific benefit of the customer(s), secondary readers of this

information should hire a licensed inspector to perform an inspection to meet

their specific needs and to obtain current information concerning this property.

www.acehomeinspections.net

Prepared Using HomeGauge http://www.homegauge.com/ SHGI (c)

2000-2003 : Licensed To Jeffrey James Aiken

Styles & Materials

REAR COVERED DRIVE-THRU

|

SLOPED OFF BUILDING

METAL

SHEETING ROOF COVERING

|

2 BRICK COLUMNS

VINYL

COVERED CEILING

|

|

Inspection Items

Styles & Materials

CONCRETE

|

ASPHALT

|

SLOPED DOWN LEFT TO RIGHT

|

RELATIVELY LEVEL PROPERTY

|

TALL TREES IN FAR REAR

|

Inspection Items

Styles & Materials

FRONT OPEN PATIO

|

CONCRETE SLAB

|

CONCRETE TABLES AND BENCHES

|

NONE

|

NONE

|

RIGHT SIDE ENTRY DOOR

|

RIGHT SIDE STEEL TUBE

RAILING

|

|

Inspection Items

Styles & Materials

FRONT ENTRY DOORS

RIGHT

SIDE ENTRY DOORS

LEFT SIDE ENTRY

DOOR

REAR ENTRY DOOR

|

FRONT METAL FULL GLASS

RIGHT SIDE METAL FULL GLASS

LEFT SIDE METAL DOOR

REAR

METAL DOOR

|

DEADBOLTS

FRONT

OUTER/INNER ENTRY

RIGHT OUTER/INNER

ENTRY

|

WOOD/HOLLOW/FLUSH

|

METAL FRAME

|

FIXED

|

DOUBLE PANE

|

BRICK

|

BRICK

|

ALUMINUM

|

POURED CONCRETE

|

VINYL AND

ALUMINUM

|

WALK ENTIRE ROOF/USE LADDER

|

FLAT

|

TAR AND GRAVEL

|

ORIGINAL

|

6 TOTAL ROOF PENETRATIONS

2 HEAT AND AIR UNITS

1

VENT SYSTEM

2 REFRIGERATION

CONDENSERS

1 FLUE

VENT

|

Inspection Items

Styles & Materials

2x4 WOOD RAFTERS

PLYWOOD

ROOF DECKING

|

2X4 WOOD CEILING JOISTS

TRUSS STYLE 2 FT AIR GAP

BETWEEN CEILING TILES AND ROOF

|

BATT

FIBERGLASS

|

6 INCHES

|

R-19

|

RAISING CEILING TILES

|

|

Inspection Items

Styles & Materials

Inspection Items

Styles & Materials

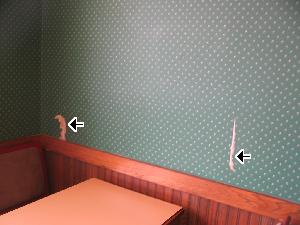

SUSPENDED CEILING TILES

|

PLASTERBOARD

VINYL WALL

SHEETING

WALLPAPER /

CHAIR-RAIL

|

CARPET

CERAMIC

TILE

|

CAKE ROOM

WATER HEATER

STORAGE ROOM

TIME CARD ROOM

|

FRONT OFFICE

LEFT SIDE

FREEZER/SINK ROOM

LEFT SIDE KITCHEN

ROOM

|

RIGHT SIDE CUSTOMER ROOM

CENTER CUSTOMER ROOM

|

CAKE ROOM SMALL SINK

CUSTOMER ROOM BOOTHS/TABLES

|

FRONT OFFICE STORAGE CLOSET

|

5 IN CUSTOMER ROOM

|

|

Inspection Items

Styles & Materials

WHITE PVC(polyvinyl chloride)

PIPING

|

GRAY PLASTIC

TUBING

|

1 MENS ROOM

1 LADIES

ROOM

|

PLASTERBOARD

|

PLASTERBOARD

|

CERAMIC TILE

|

1 CULTERED MARBLE WITH VANITY

1 WALL SINK

|

1 MENS COMMODE

1 MENS

URINAL

|

1 LADIES COMMODE

WORLD

HAND DRYERS

|

|

Inspection Items

Styles & Materials

COPPER

|

COPPER

|

PVC

|

UNKNOWN

|

PUBLIC

|

AT STREET

|

12/1986

|

NATURAL GAS

|

INSIDE STORAGE

ROOM

|

50 GALLONS

|

RUUD

|

Inspection Items

Styles & Materials

BELOW GROUND

|

IN CONDUIT

|

ALUMINUM

|

RATED 225 AMP

|

IN MAIN PANEL

|

225 AMPS

|

CIRCUIT BREAKERS

|

LEFT SIDE FREEZER ROOM

|

SQUARE D

|

SQUARE D

|

UNKNOWN

|

ROMEX

|

ALL COPPER

|

240 VOLT

FREEZERS

DEEP

FRYERS

|

200 AMP

|

CIRCUIT BREAKERS

|

SQUARE D

|

LEFT SIDE FREEZER ROOM

|

SQUARE D

200 AMP MAIN

BREAKER

|

ALL COPPER

|

LIGHTS AND OUTLETS

MISC

120 VOLTS

|

200 AMP

|

CIRCUIT BREAKERS

|

SQUARE D

|

LEFT SIDE FREEZER ROOM

|

SQUARE D

200 AMP MAIN

BREAKER

|

ALL COPPER

|

LIGHTS AND OUTLETS

MISC

120 VOLTS

|

3 TOTAL

|

Inspection Items

Styles & Materials

LEFT SIDE ROOMS

|

ROOF

|

NATURAL GAS

|

FORCED AIR

ALL-IN-ONE

PACKAGE UNIT

|

120000 BTU INPUT/HR

96000

BTU OUTPUT/HR

|

CARRIER

|

NOT MEASURED

|

UNKNOWN

|

ELECTRONIC AUTO PILOT

|

INSULATED ROUND

INSULATED

RECTANGULAR

|

12/2003

|

RIGHT SIDE ROOMS

|

ROOF

|

NATURAL GAS

|

FORCED AIR

ALL-IN-ONE

PACKAGE UNIT

|

200000 BTU INPUT/HR

160000

BTU OUTPUT/HR

|

CARRIER

|

NOT MEASURED

|

UNKNOWN

|

INSULATED ROUND

INSULATED

RECTANGULAR

|

12/2003

|

ELECTRONIC AUTO PILOT

|

Inspection Items

Styles & Materials

LEFT SIDE

|

72 DEG

|

86 DEG

|

CARRIER

|

MADE IN 12/2003

|

8 1/2

|

RIGHT SIDE ROOMS

|

73 DEG

|

78 DEG

|

CARRIER

|

MADE IN 12/2003

|

12 1/2

|

|

Inspection Items

Styles & Materials

Inspection Items

Inspection Items

Prepared Using

HomeGauge http://www.homegauge.com/

SHGI (c) 2000-2003 : Licensed To Jeffrey James Aiken